Overcoming Packaging Challenges with Pro-Stretch

Packaging; it’s normally the final stage of the journey that your product will embark on before heading out the door to your customers, but when the process is demanding and ineffective it can often cost significantly in manual effort, productivity and reducing or resolving errors. Here’s how we worked to develop a solution for one of our global customers:

The Challenge

Our customer Pro-Stretch manufactures trims and supplies five of the largest sportswear companies in the world. Typically, because they are dealing with tens of thousands of SKUs and often hundreds of thousands of units, not all of the trims may have been manufactured at the same time. Partial shipments are common, and products may be available to shipping from multiple sales orders and multiple sales order lines. The process for tracking orders and order lines for packaging, shipping and invoicing at high volumes creates a logistical challenge.

With offices located in the UK, USA, Hong Kong, Taiwan, Vietnam and China, Pro-Stretch required a packaging process that would overcome the challenges of organising what products would be prepared, boxed, shipped and invoiced at the touch of a button.

The Solution

Working closely with the Pro-Stretch team it was determined that their business process was so specific to what they do, that we needed to architect a solution that aligned with their Ascent ERP supply chain system and their operations and business processes.

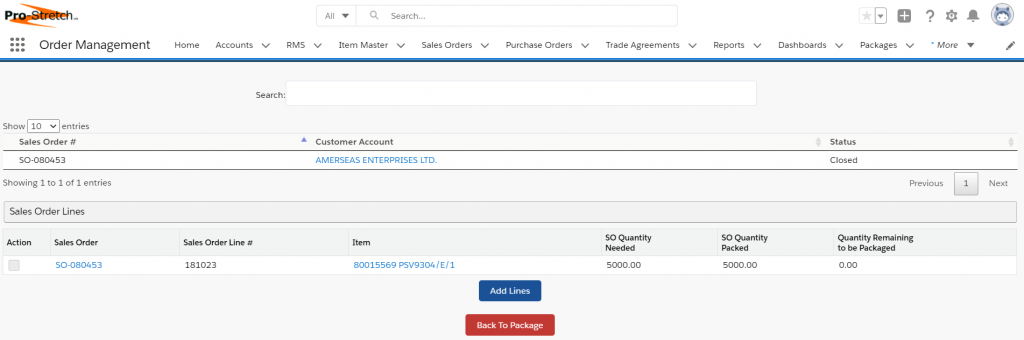

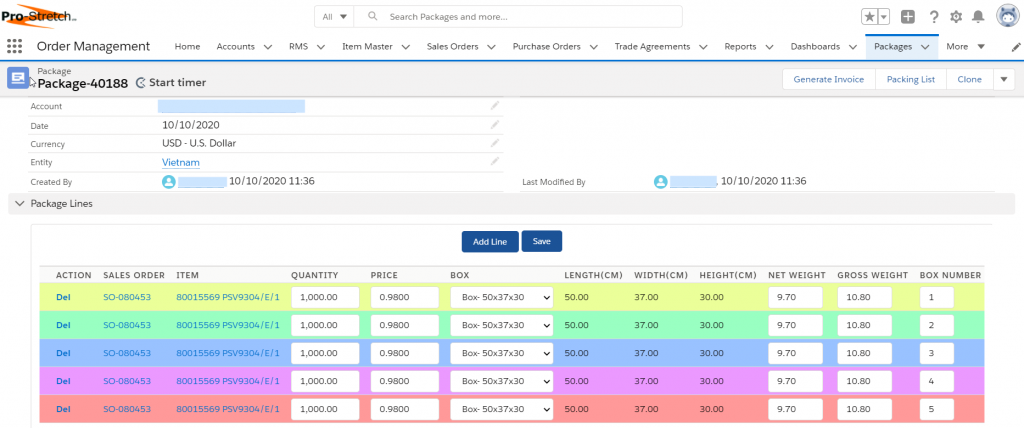

Pro-Stretch’s packaging process is both a logical group of potentially many different products across sales orders lines and potentially from across multiple sales orders, and a a number of physical boxes, cartons or pallets. A package is created in Ascent ERP to determine what sales orders and sales order lines are manufactured and ready to be grouped together for shipment. Products are then added to the package and depending on quantity and volume, physical packing boxes can be selected for one or more package lines. The package and package lines are then given to the warehouse for the physical packing and shipment.

With the large amounts of information from multiple orders, we wanted to ensure that the application was easy to use without switching browser tabs. We achieved this by developing a single screen in their ERP application which allowed all the various pieces of data to be filtered and which then allowed packages to be created from across multiple sales order lines from multiple open sales orders for any individual customer.

This allowed for the team to easily select the quantities for each of the package lines, and based on those, select from a standard set of pre-defined boxes, in turn directing the packing teams on what to ship, in what type of box, even down to the number of boxes needed for each shipment.

The Takeaways

Pro-Stretch now has a seamless packaging process as well as a wider view across the whole organisation. What’s more is that Pro-Stretch has also saved up to 60% of shipping clerk time which creates a much more efficient packaging process, with the team now able to focus energy on improving the customer delivery experience.

Struggling with a similar challenge or need to innovate your Salesforce system to work more effectively for you? Book a FREE consultation here and let’s talk about a solution.

Watch our video below to discover more details on how we helped Pro-Stretch overcome their packaging & shipping challenges.